- Compact structure

- Integrated design, modular fabrication

- Automatic operation and sturdy construction

- High efficiency

- Energy saving

- Low investment and low operational costs

- Easy to install and maintain

- Competitive factory price

- OEM or ODM available

Combined DAF Equipment

Description

Combined DAF equipment, also called combined dissolved air flotation equipment or combine DAF machine, is the extensively used wastewater treatment equipment to efficiently separate the solid pollutant from the wastewater and also resolve overall wastewater impurity issues in the wastewater treatment systems.

The combined DAF equipment can be designed of circular or rectangular configuration. In the working process, the flocculating agent PAC or PAM is added to the wastewater in the combined DAF equipment, the wastewater enters the combined air-floating contact area after an effective flocculation reaction within the specified time, dose and flocculation effect. In the contact zone, the micro bubbles in the dissolved air and the floes in the wastewater adhere to each other and enter the separation zone together. Under the action of the buoyancy of the bubbles, the flocs and the bubbles rise together to the liquid surface to form scum. Dross is scraped by the scraping device to the sludge area. The lower clear water flows through the collector to the clear water tank. Some of the clean water flows back to the dissolved gas system and the other part is discharged. Our combined DAF equipment can run smoothly and does not require operator on-site monitoring.

Combined DAF equipment Specifications

| No | Model | Capacity(m3/h) | Water Pump Power (KW) | Scraper Power (KW) | Overall Size (mm) |

|---|---|---|---|---|---|

| 1 | TDAF-3 | 3 | 3 | 0.37 | |

| 2 | TDAF-5 | 5 | 3 | 0.37 | |

| 3 | TDAF-10 | 10 | 3 | 0.37 | 4000*1200*1200 |

| 4 | TDAF-20 | 20 | 3 | 0.37 | 4800*1200*1500 |

| 5 | TDAF-30 | 30 | 4 | 0.37 | 5800*1200*1500 |

| 6 | TDAF-75 | 75 | 15 | 0.55 | 11000*2500*2000 |

| 7 | TDAF-125 | 125 | 22 | 1.1 | 13500*2800*2600 |

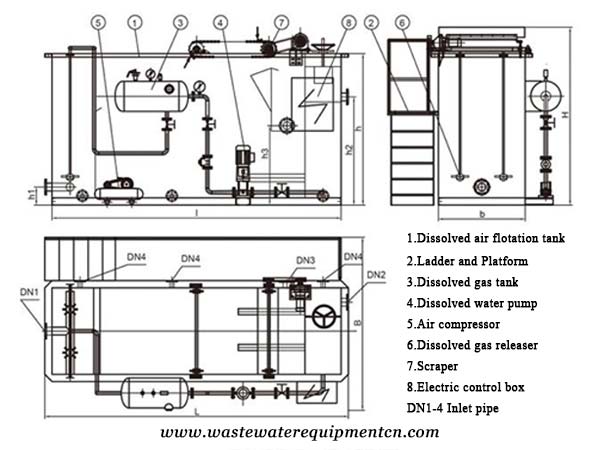

Combined DAF equipment Structure

The combined DAF equipment integrates water intake, flocculation, separation, water collection and effluent into one body. Similar to the traditional air floatation equipment, it has a steady flow chamber and a dissolved gas release chamber to make the treatment more stable and the effect is better.

Dissolved gas tank. The raw water through the folding plate reaction has a high flow rate. If it is in direct contact with the dissolved air, it will dissipate the tiny bubbles and affect the effect of the bubbles on the flocculent, thereby reducing the efficiency of air flotation and increasing the steady flow chamber. The raw water kinetic energy is consumed, and the uniform velocity enters the dissolved air water release chamber, thereby effectively ensuring the removal efficiency.

Dissolved gas releaser. The dissolved gas release chamber and the separation chamber are in one tank body. In the middle, the dissolving water and the flocculated raw water adhere to each other and rise slowly into the air flotation separation chamber, which ensures the space and time between the flocs and the micro bubbles, and the release rate of the dissolved air is 80-100%.

Combined DAF Equipment Features

- Compact structure

- Integrated design, modular fabrication

- Automatic operation and sturdy construction

- High efficiency

- Energy saving

- Low investment and low operational costs

- Easy to install and maintain

- Competitive factory price

- OEM or ODM available

Combined DAF Equipment Applications

Our combined DAF equipment is widely used for white water paper pulp recycling and water reuse, various heavy metal ions removal, refinery wastewater, oil separation, tanning wastewater impurity removal, dyeing wastewater color and impurity removal, etc.

About RUNNENG

RUNNENG had been specializing in supplying turn key wastewater treatment equipment and solution to worldwide customers for over 20 years. Our high quality wastewater equipment includes dissolved air flotation equipment, bar screen waste remover, sludge scraper and integrated sewage treatment equipment, etc. We are not only manufacturing best quality products but also providing professional engineering design and installation service. OEM and ODM are also available.

If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.